|

Flow Research

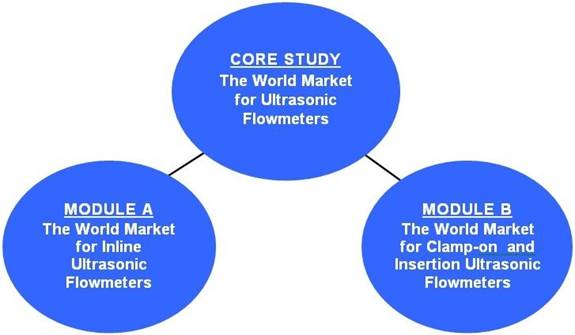

has completed a new set of three market studies on the

worldwide ultrasonic flowmeter market.

These studies determined the size of the ultrasonic flowmeter market

in 2022 with input for 2023 and forecast its market size through 2027.

This was our first look at the ultrasonic flowmeter market since the

pandemic. The three studies are called:

-

Core Study: The World Market for

Ultrasonic Flowmeters, 7th Edition

-

·Module A: The World Market

for Inline Ultrasonic Flowmeters

-

·Module B: The

World Market for Clamp-on and Insertion Ultrasonic Flowmeters

See the

forest and the trees with our three studies:

This is the 7th Edition of this study, which was previously published in

2001, 2003, 2008, 2012, 2017, and 2021. This study series includes three

components that, together, cover the entire scope of the ultrasonic

flowmeter market but can also function as standalones. The new studies

build on the knowledge gained over the years since our last full treatment

of the subject but will also represent a completely fresh look at the

market.

Creating

three separate modules for the ultrasonic study has proved to be very

enlightening. For example,

multipath inline ultrasonic flowmeters are especially important in the

fast-growing market for custody transfer of natural gas.

This ultrasonic technology type is highlighted here in Module

A, and it is analyzed in terms of dollar and unit shipments

worldwide and by region, as well as by average selling prices worldwide and

by region.

Core Study

The Core

Study of the Ultrasonic series analyzes the world market for all types of

ultrasonic flowmeters. It will include 2022 market size with reliable input

for 2023, provides

in-depth segmentation of the market by various product and geographic

categories, provides detailed market growth projections through 2027, and

includes 2022 market shares. It also includes a technology analysis,

profiles of significant supplier companies, and provides detailed market

strategies for suppliers. The studies gauge the extent of the

post-pandemic rebound that is boosting many markets.

Module A –

Inline

The inline market is quite different from the clamp-on and

insertion markets. This applies

to applications, industries, price points, and many other factors.

By isolating the inline (spoolpiece) market from the clamp-on and

insertion markets, a much more compelling and informative analysis results

This

study, Module A of the ultrasonic series, analyzes the world market

for inline ultrasonic flowmeters.

It includes a technology analysis, 2022 and 2023 market size data,

and provides in-depth segmentation of the market by various product and

geographic categories. It also

includes detailed market growth projections through 2027 for all types of

inline ultrasonic flowmeters. Detailed

market strategies are provided for suppliers.

Module B – Clamp-on and Insertion

This study, Module B of the

ultrasonic series, analyzes the world markets for clamp-on and for insertion ultrasonic flowmeters, with a

dedicated chapter for each. This

study covers 2022 and 2023 market size with detailed segmentation and

forecasts through 2027. It

includes technology analysis, 2019 market shares of major suppliers,

average selling prices, supplier profiles, product analyses, and

discussions of market circumstances and growth factors.

Detailed market strategies are provided for suppliers.

Module B: The World

Market for Clamp-On and Insertion Ultrasonic Flowmeters,

contains its own set of segmentation

designed to provide a comprehensive view of these two members of ultrasonic

flowmeter technology and its markets. There

is segmentation to address the unique qualities of these two ultrasonic

flowmeter designs. The study

segmentation specific to clamp-on and to insertion design types in the

Study Overview.

Clamp-on

and insertion ultrasonic flowmeters have established their own set of

advantages within the flow measurement market.

Clamp-on devices are highly versatile in that they can be installed

in either a portable or fixed manner, making them ideal choices for

economical meter upgrades, as check meters, and a host of other

applications. Clamp-on

ultrasonic flowmeters are suitable for use with gas, liquid, and steam

flows. Insertion devices permit

users to obtain the benefits of ultrasonic technology in virtually any line

size.

Modules

A and B Together

The two

modules analyze the inline, clamp-on, and insertion markets individually,

enabling us to separate out unit price and unit quantity data for each

technology, and to provide a distinctive analysis for each of these three

fundamentally different ultrasonic flowmeter types.

Together these three studies enable you to see both the forest

and the trees when it comes to the ultrasonic flowmeter market. Flow

Research stands alone in providing such a comprehensive analysis of the

worldwide ultrasonic flowmeter market.

Ultrasonic Flowmeter History

Tokyo

Keiki had first introduced ultrasonic clamp-on flowmeters to commercial

markets in Japan in 1963. In

1971, Badger Meter first brought clamp-on ultrasonic flowmeters to the

United States by reselling Tokyo Keiki’s meters. In 1972, Controlotron

began manufacturing its clamp-on ultrasonic flowmeters in Long Island, New

York. In the late 1970s and

early 1980s, Doppler flowmeters began to be used.

Because they were not well understood, they were often misapplied.

As a result, many users got a bad impression of ultrasonic

flowmeters during this time. In

the 1990s, transit-time emerged as the leading ultrasonic technology, and

ultrasonic meters began growing significantly in popularity and

capabilities.

In

the early 1980s, both Panametrics and Ultraflux experimented with

ultrasonic meters for gas-flow measurement. In the mid-1990s, a group

called Group Europeen de Recherches Gaziers (GERG) published a technical

monograph on ultrasonic flowmeters for gas flow measurement. A monograph

out of GERG led to increased European ultrasonic flowmeter use from 1996 to

1999.

The

GERG monograph laid the groundwork for the publication of AGA-9 by the

American Gas Association. AGA-9 lays out criteria for using ultrasonic

flowmeters for custody-transfer applications. Since its publication in June

1998, ultrasonic flowmeters have become widely used for custody transfer of

natural gas. They are especially suited for measuring gas flow in large

pipelines, easily handling flow in those above 20 inches in diameter, as

well as smaller pipelines. Its main competitors for custody transfer of

natural gas are the differential-pressure (DP) orifice meter and turbine

flowmeter.

It

used to be standard practice to divide the ultrasonic flowmeter market up

according to whether the meters are transit-time, Doppler or hybrid.

Traditional use of transit-time meters was to clean liquids, while Doppler

meters handle fluids with impurities. Hybrid meters are a combination of

transit-time and Doppler, and use one technology or the other, depending on

the fluid. In the past 10 years, transit-time suppliers made great progress

getting transit-time meters to measure fluid flows with some impurities. As

a result, Doppler and hybrid meters are less important since transit-time

meters are now used for applications previously reserved for Doppler

meters. Another reason for growth in transit-time meters is their use in

energy industries, mainly oil and gas, within which Doppler flowmeters play

no major role.

Mounting

type is now the more useful way to classify ultrasonic flowmeters, rather

than transit time vs. Doppler. Three main mounting types for ultrasonic

flowmeters include:

-

·

Inline

-

·

Clamp-on

-

·

Insertion

Inline

ultrasonic flowmeters are mounted with a meter body in the pipe. Inline

meters achieve the highest accuracy of any ultrasonic meters, and multipath

ultrasonic meters are inline meters. Multipath meters have three or more

ultrasonic signals or “paths” to determine flow velocity. This gives

them greater accuracy than single- and dual-path meters. The most common

number of paths is four, five and six, but some multi-path meters have

eight, 12 or even 18 paths. Inline meters are used for custody transfer

applications.

Clamp-on

meter disadvantages limit their usefulness in certain situations. The

ultrasonic signal can be attenuated by the pipe wall. Knowing pipe-wall

thickness and composition can be important. In addition, build-up on the

inside of the pipe wall can affect the internal diameter of the pipe.

Knowing the internal pipe diameter is important to getting a correct

flowmeter reading.

Insertion

meters are sometimes used in large pipes when a spool-piece would be

expensive. They have a cost-advantage over inline meters since there is no

meter body. Insertion meters go into a hole drilled in the pipe wall. They

are widely used in stack-gas and exhaust-flow monitoring. Here they compete

with DP flowmeters using averaging Pitot tubes and with thermal flowmeters.

Background of technology Background of technology

Ultrasonic

flowmeters have been gaining acceptance over the last decade as end-users

come to understand and appreciate the technology -- although some are just

now discovering the advantages and potential of ultrasonic flow

measurement.

The

ultrasonic flowmeter market is still a relatively new technology. Tokyo

Keiki first introduced ultrasonic flowmeters to commercial markets in Japan

in 1963. In 1972, Controlotron introduced the first clamp-on ultrasonic

flowmeter to the United States. In the late 1970s and early 1980s, Doppler

flowmeters began to be used.

Because

ultrasonic flowmeters were not well understood at first, they were often

misapplied. As a result, many users got a bad impression of the meters

during this time. It was not until the 1990s that ultrasonic flowmeters

began to be widely used for industrial applications.

The rapidly

expanding market for gas flow measurement is one of the major reasons for

strong projected growth in the ultrasonic flowmeter market. Energy,

including energy conservation, and other markets have the potential to

create even more demand, particularly as the technology improves to enable

new applications.

Advantages

Ultrasonic

flowmeters feature high accuracy, high reliability, high turndown ratios,

long service life, low maintenance, relatively low cost, valuable

diagnostics, no moving parts, and redundancy capabilities. Clamp-on

ultrasonic flowmeters, in particular, can offer redundancy by providing an

easy check of an inline meter. In addition to the traditional

advantages, suppliers are significantly improving accuracy, sensitivity,

and reliability.

Ultrasonic

flowmeters have a distinct advantage over other flowmeters:

-

Unlike Coriolis meters, ultrasonic flowmeters

do very well in large pipe sizes.

-

In large-size, natural gas pipeline

applications, ultrasonic flowmeters have the advantage over turbine and

differential pressure (DP) flowmeters of being highly accurate,

non-intrusive, and highly reliable over time, with no moving parts to

wear. They also have an advantage over DP flowmeters in that they are

largely non-intrusive, with the exception of insertion types.

-

Ultrasonic

flowmeters have an advantage over magnetic flowmeters in that they can

be used to measure the flow of nonconductive liquids, gases, and steam.

-

Ultrasonic flowmeters have an advantage over

vortex flowmeters in that they can meter low flows better than vortex

meters.

Further

sweetening the pot is the fact that average ultrasonic prices are holding

their own or even declining. In comparison, the average price for Coriolis

flowmeters has had upward pressure due to introductions of large-line size

models in the 12" - 16" diameter range.

A range of

applications

Ultrasonic

flowmeters are used in upstream applications for allocation metering, for

measuring gas and oil from test and production separators, for check

metering, and for other applications. A major use of ultrasonic flowmeters

is in the midstream segment for custody transfer of natural gas.

Multipath ultrasonic flowmeters achieve very high accuracy in measuring

both liquids and gases.

Probably

the single most important factor in the recent growth of ultrasonic

flowmeters in the past 25 years has been the rapid growth in the market for

multipath ultrasonic meters for custody transfer of natural gas. Multipath

ultrasonic meters have three or more paths. The benefit of having multiple

paths is that flow is measured at more points in the flowstream. This

enhances the accuracy of the measurement. In 1998, the

American Gas Association (AGA) approved the use of ultrasonic flowmeters

for custody transfer applications. Since that time, suppliers have

researched multipath meters and brought out new products. Probably

the single most important factor in the recent growth of ultrasonic

flowmeters in the past 25 years has been the rapid growth in the market for

multipath ultrasonic meters for custody transfer of natural gas. Multipath

ultrasonic meters have three or more paths. The benefit of having multiple

paths is that flow is measured at more points in the flowstream. This

enhances the accuracy of the measurement. In 1998, the

American Gas Association (AGA) approved the use of ultrasonic flowmeters

for custody transfer applications. Since that time, suppliers have

researched multipath meters and brought out new products.

Ultrasonic

flowmeters are also being more widely used to measure process gas and flare

gas. Insertion meters are used to measure flare gas in stacks, and

ultrasonic flowmete rs are used

more widely in the chemical and refining industries. rs are used

more widely in the chemical and refining industries.

In other

areas, the increased use of battery power supplies opens up additional

opportunities for ultrasonic flowmeters in the water and irrigation

industries as well as other applications. Battery powered flowmeters offer

low energy consumption independent of the main power grid and can help

reduce prices on the worldwide market.

How they work

There are two

main types of ultrasonic flowmeters:

A transit

time ultrasonic flowmeters has both a sender and a receiver. It

sends two ultrasonic signals across a pipe at an angle: one with the flow,

and one against the flow. The meter then measures the “transit

time” of each signal. When the ultrasonic signal travels with

the flow, it travels faster than when it travels against the flow. The

difference between the two transit times is proportional to flowrate.

Transit time

ultrasonic flowmeters are distinguished according to the number of

“paths” they have. A path is simply the path or track of the ultrasonic

pulse as it travels across the pipe and back again. Many ultrasonic

flowmeters are single or dual path, meaning that they send either one or

two signals across a pipe and back. Typically, there are two transducers

for each path; one is a sender and one is a receiver.

Doppler

flowmeters also send an ultrasonic signal

across a pipe. Instead of tracking the time the signal takes to cross

to the other side, a Doppler flowmeter relies on having the signal

deflected by particles in the flowstream. These particles are

traveling at the same speed as the flow. As the signal passes through the

stream, its frequency shifts in proportion to the mean velocity of the

fluid. A receiver detects the reflected signal and measures its frequency.

The meter calculates flow by comparing the generated and detected

frequencies. Doppler ultrasonic flowmeters are used with dirty liquids or

slurries. They are not used to measure gas flow. Doppler

flowmeters also send an ultrasonic signal

across a pipe. Instead of tracking the time the signal takes to cross

to the other side, a Doppler flowmeter relies on having the signal

deflected by particles in the flowstream. These particles are

traveling at the same speed as the flow. As the signal passes through the

stream, its frequency shifts in proportion to the mean velocity of the

fluid. A receiver detects the reflected signal and measures its frequency.

The meter calculates flow by comparing the generated and detected

frequencies. Doppler ultrasonic flowmeters are used with dirty liquids or

slurries. They are not used to measure gas flow.

Articles

about Ultrasonic Flowmeters

Previous

Studies:

The

World Market for Ultrasonic Flowmeters, 6th Edition

Published

2021

The

World Market for Ultrasonic Flowmeters, 5th Edition

Published

2017

The

World Market for Ultrasonic Flowmeters, 4th Edition

Published

2012

The World Market for Ultrasonic Flowmeters, 3rd Edition

Published

2008

The World Market for Ultrasonic Flowmeters, 2nd Edition (2003)

Provides historical perspective

The World Market for Ultrasonic Flowmeters, 1st Edition (2001)

Provides historical perspective

|